The Future of Energy Takes Center Stage at Symposium

Energy partnerships and deep expertise make the Columbia Electrochemical Energy Center a hotbed of activity for entrepreneurs advancing the clean energy transition.

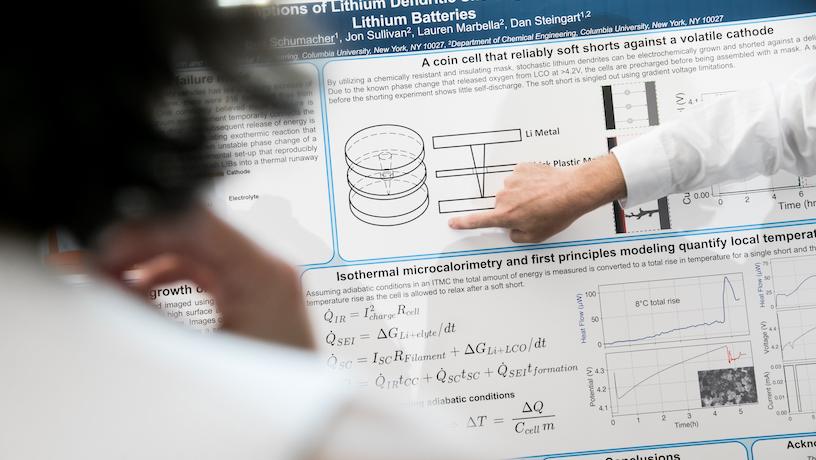

A researcher presents new findings at the CEEC Fall Symposium. Credit: Timothy Lee/Columbia Engineering

The Columbia Electrochemical Energy Center (CEEC) hosted its second annual Fall Symposium Sept.13 in Pulitzer Hall at Columbia University’s Morningside campus.

In faculty talks, industry panel discussions, and poster sessions, attendees learned about innovations happening in CEEC labs and about collaborations with industry partners.

“The entire point of CEEC is to accelerate the energy transition by accelerating the adoption of electrochemical technologies at scale,” said CEEC Co-director Dan Steingart, the Stanley-Thompson Professor of Chemical Metallurgy and a professor of chemical engineering at Columbia Engineering.

In his opening remarks, Steingart explained the importance of academic-industry partnerships. “We want to be pulled into reality – we want to solve relevant and important problems,” he said.

To that end, the symposium featured several startups founded by CEEC faculty and students and based on insights and technology developed in the center’s labs.

Carbon-neutral chemical production

Petroleum isn’t just used to generate energy. A wide range of vital materials are made of chemicals derived from fossil fuels. Columbia Engineering PhD alumna Marissa Beatty founded a company, now called Turnover Labs, that manufactures electrolysis devices to help decarbonize the chemical manufacturing industry.

“By using renewable electricity, instead of fossil fuel-powered heat, we're able to synthesize the most basic chemical building blocks out of the CO2 being emitted by chemical production facilities,” Beatty said. “Our designs emphasize durability and process compatibility, which makes our electrolyzers more resilient, less expensive, and able to scale to many different processes.”

Turnover Lab’s underlying technology is based on Beatty’s doctoral research, conducted under Dan Esposito, associate professor of chemical engineering.

“We started our company's journey in Columbia's Solar Fuels Engineering Laboratory, where we investigated novel catalyst architectures that could support and improve electrolysis across many different reactions,” Beatty said.

A new generation of gravity-based batteries

Lithium-ion batteries are the most mature technology used to store renewable energy, but they’re expensive to build and rely on scarce materials. Columbia Engineering PhD candidate Robert Mohr founded Innate Energy, a company that is building zinc batteries for grid energy storage. Similar systems typically have expensive components and complex designs, leading to manufacturing challenges and short lifetimes.

“Our system replaces the function of these expensive components with the action of gravity and buoyancy,” Mohr said. “We can provide an energy storage solution that is cheaper than lithium-ion without the flammability issues and supply chain constraints that weigh on scaling of energy storage currently.”

Mohr credited CEEC with providing the expertise and connections necessary to catalyze the development of this exciting technology.

“The close ties between CEEC and industry are a big factor in my path to starting a company. I have been exposed to not just the scientific challenges of batteries, but also the practical and engineering problems which often end up being the most important part of moving a technology out of the lab,” he said.

Cheaper batteries made from more reliable materials

The founders of startup Standard Potential are developing another alternative to lithium-ion batteries. Columbia Engineering postdoctoral researchers Richard May PhD’23 and Andrew Wang are working to produce sodium-ion cathode materials and cells.

“Sodium-ion battery chemistries allow us to use domestically available, geologically abundant, cheaper, and price-stable raw materials — as well as simplified manufacturing processes which are inherently suited for U.S.-centered battery production,” May said.

The founders credit Columbia Engineering and Dan Steingart in “helping us understand the commercial battery landscape and the technical, economic, and geopolitical holes that need to be filled in the battery supply chain,” May said.

Researchers, students, and investors gathered for CEEC's 2023 Fall Symposium. Credit: Timothy Lee/Columbia Engineering

Learn More

For more information about the symposium, see a copy of the agenda.

Learn more about CEEC on the Center’s website.