Strong as Glass

By building a structure out of DNA and then coating it with glass, a research team led by Oleg Gang has created a very strong material with very low density.

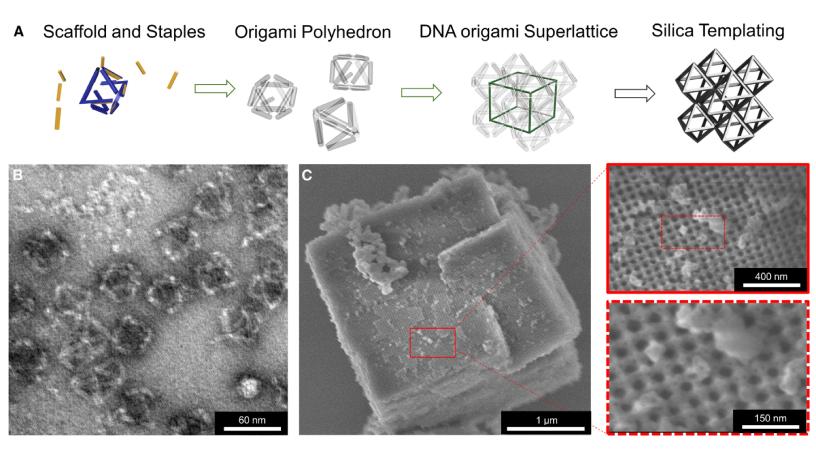

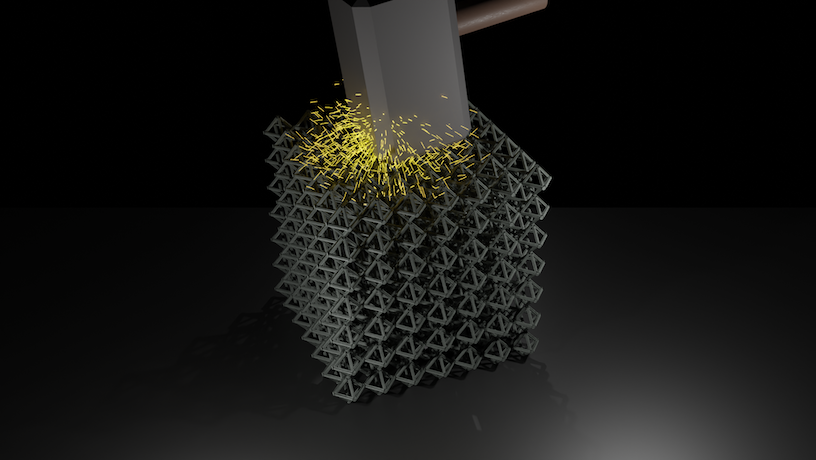

Illustration of the nanoscale-ordered frameworks formed by DNA assembly and silica templating methods demonstrate a high compressive strength, which puts this material at the top of the performance in its class. Credit: Aaron Michelson/Columbia Engineering and Brookhaven National Laboratory

Materials that are both strong and lightweight could improve everything from cars to body armor. But usually, the two qualities are mutually exclusive. Now, researchers from Columbia Engineering, University of Connecticut (UConn), and Brookhaven National Lab (BNL) have developed an extraordinarily strong, lightweight material using two unlikely building blocks: DNA and glass.

“An ability to structure materials into prescribed architectures at nanoscale was envisioned as a way to enhance its mechanical properties, but there is no easy way to build at such small scales. Our DNA-based self-assembly strategy now demonstrates that it is possible,” says Oleg Gang, professor of chemical engineering and of applied physics and materials science at Columbia Engineering and a scientist at BNL who directed the work published July 19 in Cell Reports Physical Science.

“For the given density, our material is the strongest known," says Seok-Woo Lee, a materials scientist at UConn who co-directed the study.

Strength is relative. Iron, for example, can take seven tons of pressure per square centimeter. But it’s also very dense and heavy, weighing 7.8 grams/cubic centimeter. Other metals, such as titanium, are stronger and lighter than iron. And certain alloys combining multiple elements are even stronger. Strong, lightweight materials have allowed for lightweight body armor, better medical devices, and made safer, faster cars and airplanes. The easiest way to extend the range of an electric vehicle, for example, is not to enlarge the battery but rather make the vehicle itself lighter without sacrificing safety and lifetime. But traditional metallurgical techniques have reached a limit in recent years, and materials scientists have had to get even more creative to develop new lightweight high-strength materials.

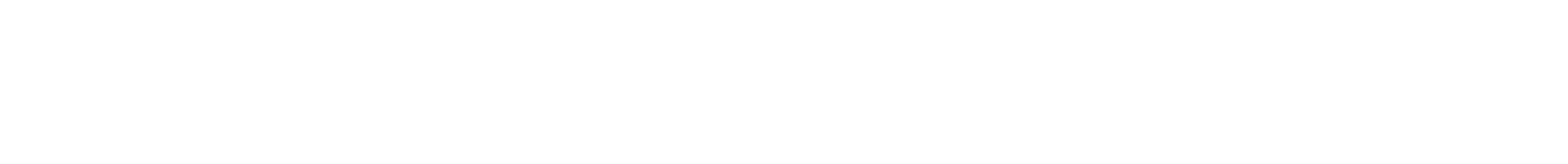

Materials scientists from Columbia Engineering, UConn, and BNL built an exceptionally strong, lightweight material out of DNA scaffold that allowed the formation of nanostructured silica, a glass-like material. The series of images at the top (A) shows how the skeleton of the structure is assembled with DNA, then coated with glass. (B) shows a transmission electron microscope image of the material, and (C) shows a scanning electron microscope image of it, with the two right-hand panels zooming in to features at different scales.

The power of glass

Credit: Aaron Michelson/Columbia Engineering and Brookhaven National Laboratory

Now, Gang and colleagues report that by building a structure out of DNA and then coating it with glass, they have created a very strong material with very low density. Glass might seem a surprising choice, as it shatters easily. However, glass usually shatters because of a flaw–such as a crack, scratch, or missing atoms–in its structure. A flawless cubic centimeter of glass can withstand 10 tons of pressure, more than three times the pressure that imploded the Oceangate Titan submersible near the Titanic this summer.

It’s very difficult to create a large piece of glass without flaws. But the researchers knew how to make very small flawless pieces. As long as glass is less than a micrometer thick, it’s almost always flawless. And since the density of glass is much lower than metals and ceramics, any structures made of flawless nano-sized glass should be strong and lightweight.

The team created a structure of self-assembling DNA. Almost like Magna-Tiles, pieces of DNA of specific lengths and chemistry snapped themselves together into a skeleton of the material. Imagine the frame of a house or building, but made of DNA.

Gang and Aaron Mickelson, a postdoctoral student in the Gang lab at at Columbia Engineering and a scientist at Brookhaven’s Center for Functional Nanomaterials, then coated the DNA with a very thin layer of glass-like material only a few hundred atoms thick. The glass only just coated the strands of DNA, leaving a large part of the material volume as empty space, much like the rooms within a house or building. The DNA skeleton reinforced the thin, flawless coating of glass making the material very strong, and the voids comprising most of the material’s volume made it lightweight. As a result, glass nanolattice structures are four times higher in strength but five times lower in density than steel. This unusual combination of lightweight and high strength has never been achieved before.

“The ability to create designed 3D framework nanomaterials using DNA and mineralize them opens enormous opportunities for engineering mechanical properties. But much research work is still needed before we can employ it as a technology,” says Gang.

The team is currently working with the same DNA structure but substituting even stronger carbide ceramics for glass. They have plans to experiment with different DNA structures to see which makes the material strongest. Future materials based on this same concept have great promise as energy-saving materials for vehicles and other devices that prioritize strength. Lee believes that DNA origami nanoarchitecture will open a new pathway to create lighter and stronger materials never imagined before.

He notes, “I am a big fan of Iron Man movies, and I have always wondered how to create a better armor for Iron Man. It must be very light for him to fly faster. It must be very strong to protect him from enemies' attacks. Our new material is five times lighter but four times stronger than steel. So, our glass nanolattices would be much better than any other structural materials to create an improved armor for Iron Man.”